Post by shubert on Jun 16, 2010 12:57:12 GMT -5

ok this right up is for a freind in maylaysia that is sorta new to the gze world. hes got a peske b18 , hes trying to kill at the track , and ive been chattin with him via IM for the last 2 weeks helping him with his car. so far so good. well he has a gze with sc14, and oversized crank pulley , adj fuel pres reg. and a few other things. his screen name is miriguy , and hopefully hell join ccc , so i decided to host this write up for him here , that way he'll check the sight out.

anyway , he sought out a set of blluetop cams to help pull a little more up top. but upon install , and being his first time , tdc may not be acurate.

so first lets understand tdc.

"TDC" or top dead center refers to the position of the engines crank and rod assemblies. but more on the crank position than anything. this is the base that almost any engine builder starts with when assembling an engine. basically , it is putting the #1 pistons crank stroke at the top of the compression stroke. tdc is tdc , no matter wahat unless your working on a rotex or other rotary engine. tdc is the starting position of the crank upon engine building simply because everytihng else lines up with this marking , to ensure everything is happening at the right time for the motor to operate in unison and harmony.

finding tdc.

on just about every engine's crank theres a "TDC" OR "TIMING" mark. as opposed on the engine itself , there is a "tdc degree" or timing mark". when you line these up , you get "TDC" . now in some instances , there are no marks like this , so what to do? ive included a few links below for more reading on that.

wiki.answers.com/Q/How_do_you_find_the_top_dead_center_on_your_engine

www.wikihow.com/Find-Your-Engine's-Top-Dead-Center-(TDC)

if none of these methids are available , due to an oversized pulley there are marks on the timing belt pulley and oil pump to also find tdc. if using a flashlight , and looking down into the timing belt cover you can see the oil pump , and the timing gear pulley. on the oil pump you will see this little nipple. . .

now , use the mark on the timing gear pulley and line it up with the nipple .. .

that is also a way of getting tdc on a 4ag.

ok , so now you know what tdc is , and how to get it , now lets use that knowledge and install some cams.

ok , first step , is were gonna find tdc , for these example pics , we use a 2tc , and the 4ag (being the latter)

ok , now that your engine is at tdc , you may proceed to remove your cams. if this is something that should be explained , set down the tools, and step away slowly.

ok so now were putting our cams back in . at this point you should have all the cam bearing caps back on in their order , everything assembly lubed , and fasteners torqued down to factory specs. tightening sequence should also be used. for 4ag goesas fallows . .

4-2-1-3-5 meaning you start in the middle at number one then tighten the corresponding next in senquence to 9-11 lbs.-ft. torque depending on what viscosity oil youll be using.

now lining the cams up , is a pretty simple ordeal. to tell the difference in intake and exhaust cams , the exhaust cam has a spline gear on it , that drives the distributer shaft.

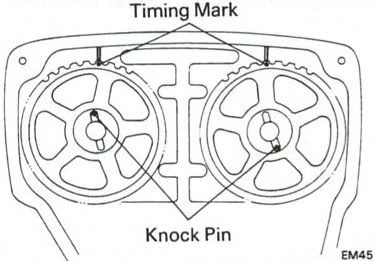

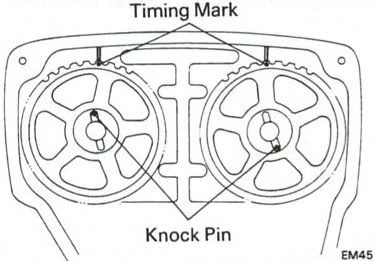

when installing there are sure ways to ensure cams are properly "clocked" when being installed. on the cams there are knock pins for clocking , and on the cam gears them selves there are timing marks. on the backing plate behind the cam gears , there are marks to line up the cam gears marks with. all explained below.

according to this diagram ,this is how the pins should be clocked during installation . . now this dont have to be exact as long as its in the general vincinity , because with the cam gears you can fine adjust the timing marks before installing the timing belt

in this next picture , you can see i colored the knock pins silver , to better see. . . .

ok , now you can put your cam gears on , theres a few tricks to this , most newbise will remove al of the plastic covers on the timing belt side , to access the tensioner. theres an easer way if you have the strengh and patients. go ahead and put out on the intake cam gear and line up the timing mark with the backing plate like showed . . . i highlighted the timing mark on the cam gear and backing plate with silver for ease of veiwing.

after putting on your intake cam gear , pull the timing belt tight , and slide it half way onto the intake cam gear , making sure there is no play in the belt back towards the bottom ofthe engine. then using your exhaust cam gears , set it in the belt , and pull the belt towards the exhaust cam. you may have to readjust the gear a few teeth to make it look as if it were lined up before putting it on the cam shaft. this may take a few tries , but beats pulling the covers off of the entire side of the engine, when putting the exhaust cam gear on , be sure your intake cam gear doesnt move of of it mark. when you get the belt on , it should look like this . . . . .

if you opt to do it the old fasion way , and remove all the covers and loosen the tensioner , then the cam gears would look like this , before putting the belt on.

now the last step , is to pull out your CAS , or cam angle sensor (on gze only) or distributer , and realign the "marks" on the distributer shaft. slide distributerback in careful not to turn it at all.

cam gear bolts are tourqued to 34 lbs-ft. torque w/ loctite 242.

anyway , he sought out a set of blluetop cams to help pull a little more up top. but upon install , and being his first time , tdc may not be acurate.

so first lets understand tdc.

"TDC" or top dead center refers to the position of the engines crank and rod assemblies. but more on the crank position than anything. this is the base that almost any engine builder starts with when assembling an engine. basically , it is putting the #1 pistons crank stroke at the top of the compression stroke. tdc is tdc , no matter wahat unless your working on a rotex or other rotary engine. tdc is the starting position of the crank upon engine building simply because everytihng else lines up with this marking , to ensure everything is happening at the right time for the motor to operate in unison and harmony.

finding tdc.

on just about every engine's crank theres a "TDC" OR "TIMING" mark. as opposed on the engine itself , there is a "tdc degree" or timing mark". when you line these up , you get "TDC" . now in some instances , there are no marks like this , so what to do? ive included a few links below for more reading on that.

wiki.answers.com/Q/How_do_you_find_the_top_dead_center_on_your_engine

www.wikihow.com/Find-Your-Engine's-Top-Dead-Center-(TDC)

if none of these methids are available , due to an oversized pulley there are marks on the timing belt pulley and oil pump to also find tdc. if using a flashlight , and looking down into the timing belt cover you can see the oil pump , and the timing gear pulley. on the oil pump you will see this little nipple. . .

now , use the mark on the timing gear pulley and line it up with the nipple .. .

that is also a way of getting tdc on a 4ag.

ok , so now you know what tdc is , and how to get it , now lets use that knowledge and install some cams.

ok , first step , is were gonna find tdc , for these example pics , we use a 2tc , and the 4ag (being the latter)

ok , now that your engine is at tdc , you may proceed to remove your cams. if this is something that should be explained , set down the tools, and step away slowly.

ok so now were putting our cams back in . at this point you should have all the cam bearing caps back on in their order , everything assembly lubed , and fasteners torqued down to factory specs. tightening sequence should also be used. for 4ag goesas fallows . .

4-2-1-3-5 meaning you start in the middle at number one then tighten the corresponding next in senquence to 9-11 lbs.-ft. torque depending on what viscosity oil youll be using.

now lining the cams up , is a pretty simple ordeal. to tell the difference in intake and exhaust cams , the exhaust cam has a spline gear on it , that drives the distributer shaft.

when installing there are sure ways to ensure cams are properly "clocked" when being installed. on the cams there are knock pins for clocking , and on the cam gears them selves there are timing marks. on the backing plate behind the cam gears , there are marks to line up the cam gears marks with. all explained below.

according to this diagram ,this is how the pins should be clocked during installation . . now this dont have to be exact as long as its in the general vincinity , because with the cam gears you can fine adjust the timing marks before installing the timing belt

in this next picture , you can see i colored the knock pins silver , to better see. . . .

ok , now you can put your cam gears on , theres a few tricks to this , most newbise will remove al of the plastic covers on the timing belt side , to access the tensioner. theres an easer way if you have the strengh and patients. go ahead and put out on the intake cam gear and line up the timing mark with the backing plate like showed . . . i highlighted the timing mark on the cam gear and backing plate with silver for ease of veiwing.

after putting on your intake cam gear , pull the timing belt tight , and slide it half way onto the intake cam gear , making sure there is no play in the belt back towards the bottom ofthe engine. then using your exhaust cam gears , set it in the belt , and pull the belt towards the exhaust cam. you may have to readjust the gear a few teeth to make it look as if it were lined up before putting it on the cam shaft. this may take a few tries , but beats pulling the covers off of the entire side of the engine, when putting the exhaust cam gear on , be sure your intake cam gear doesnt move of of it mark. when you get the belt on , it should look like this . . . . .

if you opt to do it the old fasion way , and remove all the covers and loosen the tensioner , then the cam gears would look like this , before putting the belt on.

now the last step , is to pull out your CAS , or cam angle sensor (on gze only) or distributer , and realign the "marks" on the distributer shaft. slide distributerback in careful not to turn it at all.

cam gear bolts are tourqued to 34 lbs-ft. torque w/ loctite 242.

Aww man, at least you tried. What are you planning to try next?

Aww man, at least you tried. What are you planning to try next?