Post by KING7thGen on Jun 8, 2010 23:20:11 GMT -5

ok my friend send me this dunno where its from

I have my 94 Celica 7AFE head off for resurfacing and head gasket and I wanted to replace the valve seals.

I was about to do the same thing, but mine looked like it would still not fit. The clearance between the lifter bores and the tiny springs just seemed too tight. Earlier in the day I stopped by a motorcycle shop and saw what they were using and it was something like this: www.pitposse.com/vaspco.html

I thought that really looks like my hardware store C-clamp. So I took a piece of aluminum bar that I had laying around - most hardware stores carry it. It was @ 3/16" thick, 1 1/2" wide and I hammered one end around a steel bar to get it to "curl at the end. I also used vice grips to bend it into shape. I cut off the curled end with a hack saw. Ultimately I needed the radius to be pretty tight so I finished the forming using a steel pin from a trailer hitch. What I ended up with was something like this:

In Theory here is how it would be used:

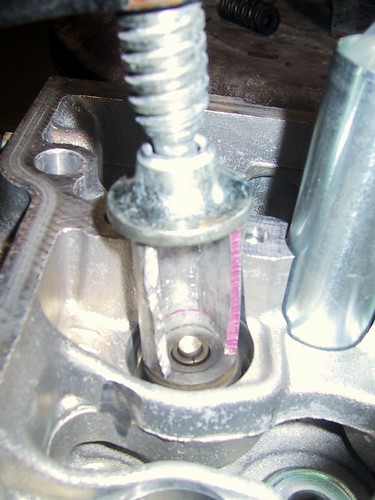

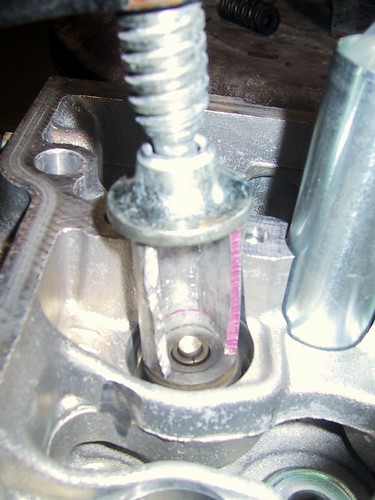

Here it is in use:

High res pictures are on Flickr:www.flickr.com/photos/9237872@N05/

It worked like a charm - The only thing I had to be careful with was because the clamp is heavy, It wanted to tip over and made it a little unstable, but all you need to do it steady it with one hand and once compressed, grab the keepers with a pen magnet.

Pulling the valve seals off was a little difficult, but needle nose pliers and vise grips worked. to install I was a little paranoid about getting the seal seated and straight, but a 10 mm socket with 3" ext worked fine. I hammered it until it sounded solid.

I have my 94 Celica 7AFE head off for resurfacing and head gasket and I wanted to replace the valve seals.

I was about to do the same thing, but mine looked like it would still not fit. The clearance between the lifter bores and the tiny springs just seemed too tight. Earlier in the day I stopped by a motorcycle shop and saw what they were using and it was something like this: www.pitposse.com/vaspco.html

I thought that really looks like my hardware store C-clamp. So I took a piece of aluminum bar that I had laying around - most hardware stores carry it. It was @ 3/16" thick, 1 1/2" wide and I hammered one end around a steel bar to get it to "curl at the end. I also used vice grips to bend it into shape. I cut off the curled end with a hack saw. Ultimately I needed the radius to be pretty tight so I finished the forming using a steel pin from a trailer hitch. What I ended up with was something like this:

In Theory here is how it would be used:

Here it is in use:

High res pictures are on Flickr:www.flickr.com/photos/9237872@N05/

It worked like a charm - The only thing I had to be careful with was because the clamp is heavy, It wanted to tip over and made it a little unstable, but all you need to do it steady it with one hand and once compressed, grab the keepers with a pen magnet.

Pulling the valve seals off was a little difficult, but needle nose pliers and vise grips worked. to install I was a little paranoid about getting the seal seated and straight, but a 10 mm socket with 3" ext worked fine. I hammered it until it sounded solid.

Aww man, at least you tried. What are you planning to try next?

Aww man, at least you tried. What are you planning to try next?