Post by Wickedtoyz on Dec 27, 2011 14:38:39 GMT -5

Found this write up on ToyotaNation by kaitaiya

due to popular demand i will be creating a semi step by step how to swap i did on my 93 corolla when i swapped in my Blacktop 4age from a AE111 Levin. i performed this swap over a year ago so i maybe missing a few things.

it's done please feel free to ask any questions. i will be more than happy to share what i've learned along this build.

on a side note i'm actually looking at another BT and might pick it up tomorrow. if i do i will make my own wiring harness and share that experience here as well.

thanks, JD

it's done please feel free to ask any questions. i will be more than happy to share what i've learned along this build.

on a side note i'm actually looking at another BT and might pick it up tomorrow. if i do i will make my own wiring harness and share that experience here as well.

thanks, JD

ok starting from the beginning. i had been contemplating a swap into my car for a while now. Having an AE102, there were a lot of options. things that crossed my mind were 4age 16V, 4agze, 3sgte, 4age 20v, 3sgte, 7age, 1MZFE. i actually wanted to put in a V6 into my car, but sourcing everything would become a problem. actually now i do have access to a V6/5 speed from a Solara so there is a chance i might still do it in the future. But that will be another write up. This will only concern my AE102 with a JDM 4age 20V blacktop. what i encountered, what you may encounter if you choose this path, some hints and tricks that might make things easier for you. This car is my daily driver and i've already put 10K miles on it in a year without doing a tear down or even taking the trans off to check the clutch. i figured when i did it, the Clutch would be easy to do if i needed to, and as with most every ebay auction, they only allow 30day startup warranty. so i figure i should get it in as soon as possible to make sure it would start. being that my car developed a knock i had to do something so this was the path i chose.

this is my car. it's a 93 AE102 corolla. it started out life with a 7AFE/auto. as you can see i already had JDM lights front and rear on it. i also have H&R springs, kyb GR-2 struts and camber bolts.

this is what i bid on and won on ebay sitting in the back of my truck once i picked it up from the shipping dock. if you choose to do a 20V swap, try to get an as complete as possible setup. i got a whole clip just to make sure nothing was missing. i think i could have probably gotten it to fire up if i put a fuel pump on it and turned it on. i even had the key and batter in my clip.

this is my car. it's a 93 AE102 corolla. it started out life with a 7AFE/auto. as you can see i already had JDM lights front and rear on it. i also have H&R springs, kyb GR-2 struts and camber bolts.

this is what i bid on and won on ebay sitting in the back of my truck once i picked it up from the shipping dock. if you choose to do a 20V swap, try to get an as complete as possible setup. i got a whole clip just to make sure nothing was missing. i think i could have probably gotten it to fire up if i put a fuel pump on it and turned it on. i even had the key and batter in my clip.

just a word to the wise, if you plan to pick up something like this in a 1/2 ton truck that's loaded with a forklift, when taking it out with an engine hoist, it's a little off balance. and it swung out once i got it high enough. it's really off balance and you will need to transfer your front hook from the 7afe/4afe because the 20V blacktop( i will be referring to it as BT for future reference and ST for silver top) does not have one. doing this will give you a point on the front of the engine to attach a chain for the engine hoist. some models of corolla i have found it easier to lower the engine out of the bottom, but in my pictures i pulled it from the top. i will illustrate some of the issues with this and what can be done as well.

here is a picture of my 7afe showing the engine hook on the front of the engine that i transferred to my BT.

here is a picture of my 7afe showing the engine hook on the front of the engine that i transferred to my BT.

with any tear down, you will want to start by removing the radiator, washer tank, battery, airbox or short ram intake if you had one like i did. you can drain fluids at this time, but i chose not to drain the oil from the engine because it would be contained. you need to make sure your car is supported on jackstands and also remove the lower shielding from the engine bay. do not cut any wires or hoses. you will need to reuse some of these. take the time to get them off stock. you may need to use a small screw driver to depress the tab in order to get it to release. the hoses i found it easier to use a channel lock pliers to loosen the hoses that are stuck on once you get the clamp off. just use caution with the heater hoses. they are brass and do bend really easy. i wound up crushing them a bit, but used the handle of my ratchet to straighten them out back to round.

in these pictures you can see i have the radiator out. the pan under the car i got from home depot in their masonry section. it's 2'x3' and catches EVERYTHING. you can catch a whole radiator, trans, engine oil all at once if you choose to. i think it was $12 but i can't remember. i have like 4 of them that my friends keep borrowing. make sure you dispose of fluids according to your local laws. protect the environment. also i chose to support the car with the front tow hook area because i needed to swap the lower sub frame from my car. i got put into a wall once by a careless SUV owner and wasn't sure if the drivers arm might have been bent. i hit hard enough to bend a steel scion XB wheel so i would think there was some damage.

i also put the clip nose to nose with my car in order to be able to compare notes and see what i would need to change and compare. if you take note of the small moving cart under my clip those are life savers. i used 2 of them(rated at 1200lbs each) to move the clip from my driveway into the garage. they are $20 at home depot in the hand truck area, and will easily support an engine for moving around when needed. you will see them throughout this build.

on a side note, i am not employed with Home depot, nor do i have stocks in the company. it's just one of the resources i used out here in paradise. so please don't take offense if you don't like big orange.

in these pictures you can see i have the radiator out. the pan under the car i got from home depot in their masonry section. it's 2'x3' and catches EVERYTHING. you can catch a whole radiator, trans, engine oil all at once if you choose to. i think it was $12 but i can't remember. i have like 4 of them that my friends keep borrowing. make sure you dispose of fluids according to your local laws. protect the environment. also i chose to support the car with the front tow hook area because i needed to swap the lower sub frame from my car. i got put into a wall once by a careless SUV owner and wasn't sure if the drivers arm might have been bent. i hit hard enough to bend a steel scion XB wheel so i would think there was some damage.

i also put the clip nose to nose with my car in order to be able to compare notes and see what i would need to change and compare. if you take note of the small moving cart under my clip those are life savers. i used 2 of them(rated at 1200lbs each) to move the clip from my driveway into the garage. they are $20 at home depot in the hand truck area, and will easily support an engine for moving around when needed. you will see them throughout this build.

on a side note, i am not employed with Home depot, nor do i have stocks in the company. it's just one of the resources i used out here in paradise. so please don't take offense if you don't like big orange.

ok so continuing with the teardown.

*HINT #1*

if you have lowered suspension or choose not to want to pay for alignment again, pay attention to how i took apart the strut. most people take the strut off the spindle at the camber bolts. if you take the 3 nuts off the top and take the 2 17mm nuts and one 17mm bolt from the ball joint, you can just pop off the steering tire rod end and pull the whole strut assembly off as one piece including the spindle and rotor. you can see the struts i pulled off the clip sitting behind it with the brake rotor and hub still attached. this allows you to bolt it all back together and not worry about alignment.

don't forget to support the caliper with a piece of tie wire, and you will need to use a big enough socket and possibly a crow bar wedged in to break the nut loose if someone went ahead and impacted it on before you. when you put this back on, it should be tight, but there is no need to impact it on. the cotter pin and castle nut will retain it. with all the road grime, water, salt it may eventually rust weld itself to the CV joint.

*HINT #1*

if you have lowered suspension or choose not to want to pay for alignment again, pay attention to how i took apart the strut. most people take the strut off the spindle at the camber bolts. if you take the 3 nuts off the top and take the 2 17mm nuts and one 17mm bolt from the ball joint, you can just pop off the steering tire rod end and pull the whole strut assembly off as one piece including the spindle and rotor. you can see the struts i pulled off the clip sitting behind it with the brake rotor and hub still attached. this allows you to bolt it all back together and not worry about alignment.

don't forget to support the caliper with a piece of tie wire, and you will need to use a big enough socket and possibly a crow bar wedged in to break the nut loose if someone went ahead and impacted it on before you. when you put this back on, it should be tight, but there is no need to impact it on. the cotter pin and castle nut will retain it. with all the road grime, water, salt it may eventually rust weld itself to the CV joint.

*HINT #2*

when removing the engine there's a couple different ways to do it. i removed it from the top because i am still somewhat stuck on the old school method. after pulling a few of these, i've found that it is possible to pull it from the bottom as well.

Pulling from the top:

you will need to remove the CV joints,

pull out the wiring and tuck it onto the motor or remove it completely,

use caution to tilt the engine out of the engine bay

possibly remove the hood.

You can see the engine was tilted to the trans side to clear the trans mount. you can remove the trans mount to gain some clearence when pulling the engine. most times you will have trouble with the back mount. this one for some reason will not come out straight sometimes. you can use a small hammer to tap out the stud that goes through the stud closest to the passenger side(us passanger) and it will allow the mount to slip out easier if you come from the top. when you put the engine back in, you can simply put the stud back in and use an impact gun to run it back in.

Pulling the engine from the bottom.

you will need to again remove the wiring, or tuck it onto the engine.

one of the benefit of removing from the bottom, you can leave the CV joints in(just make sure they are not captive like passing through the frame) doing this allows you to not have to spill trans fluid ALL OVER everything. then again you should use the drain plug and drain the fluids first. but if you take a good look at the pics you can see i didn't and there's fluid residue all over the garage floor.

when you plan to remove from the bottom, you will need to remove the whole subframe. there should be 8-12 bolts depending on what your suspension is like. the clip i had used a different lower arm than my car did. so luckily i had an extra subframe from another parts car and i used that instead. if you choose to do it this way, the Home depot dolly comes in handy. you can place one under the engine/subframe and then use the engine hoist to lower the engine onto the dolly. once everything is free, then you can use the engine hoist to raise the body of the car over the engine and roll the engine out. i've successfully done it this way several times.

when you have the parts out, this is the perfect time to change sway bar if you choose to. fishing it through the suspension and over the exhaust is kind of a bear.

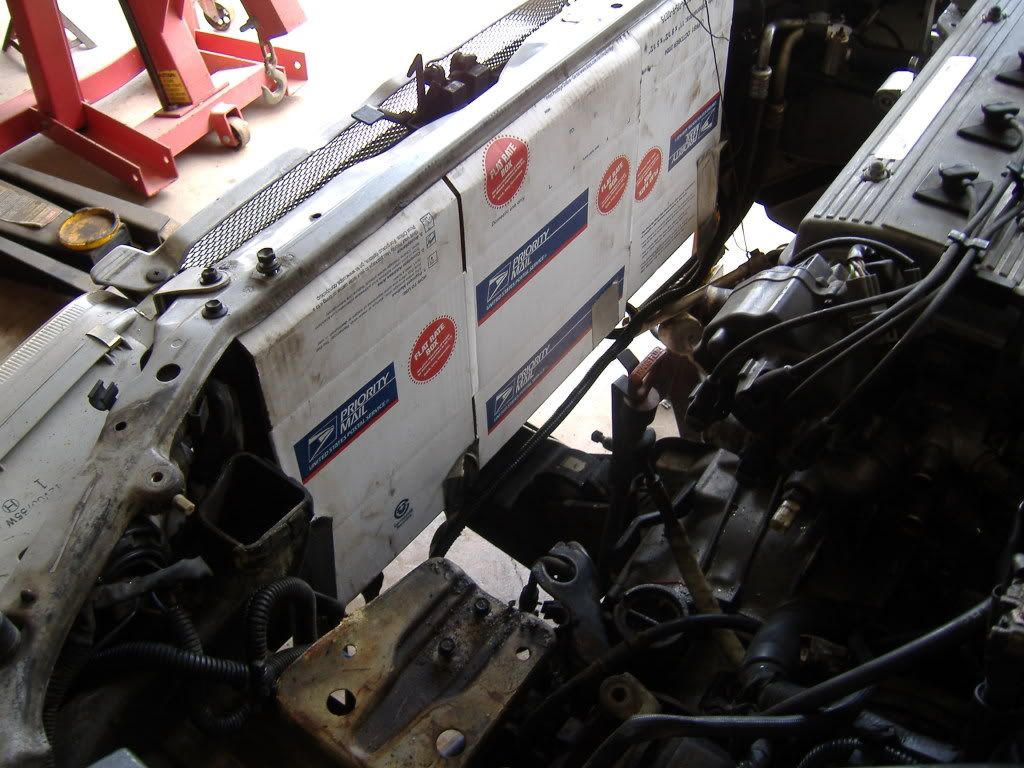

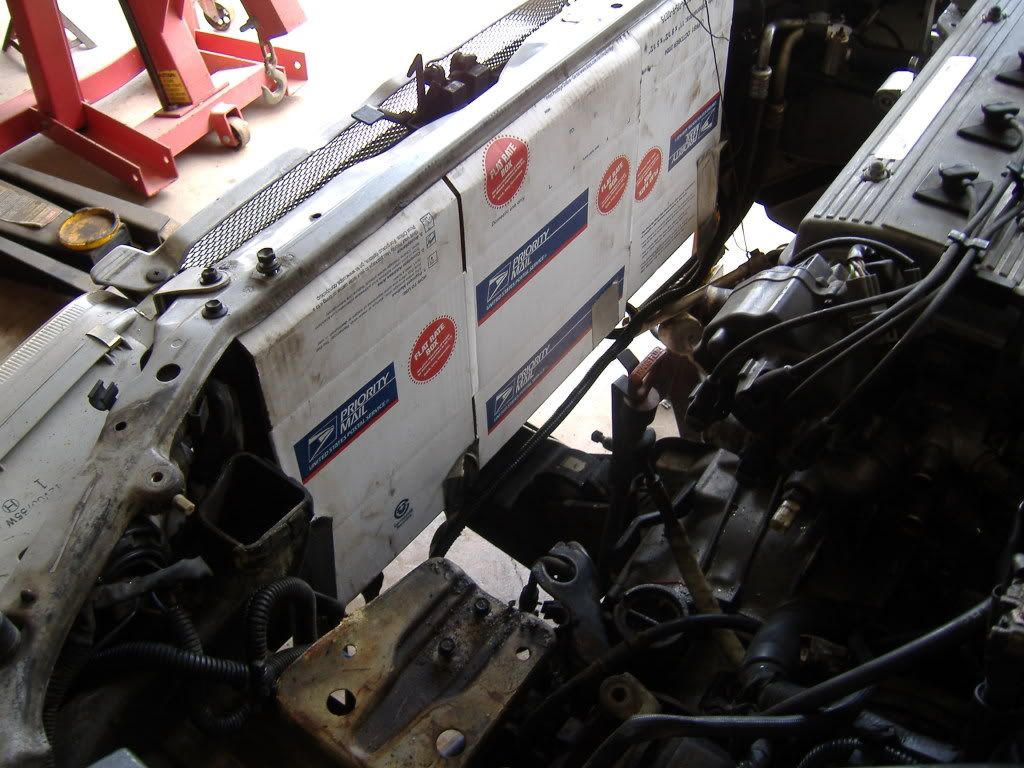

below are the pictures associated with this. you can see i used some cardboard to protect the condenser while i pulled the engine. i also pulled the AC compressor on the side and used a piece of wire to tie it up out of the way. i could have made a mount to adapt it to the 20V mount like my friend did, but instead i used the 20V compressor. make sure you remove all rubber lines, hard lines, wires, etc and support the engine with an engine hoist prior to removing any engine mount bolts.

you can see the differences in the sub frame here. also the AE92 subframes are different as well so if you choose to somewhat follow this for an AE92 swap please make note of your sub frame

swapping the swaybar

Engine out. you can see the back mount was removed from the engine mount bolt. i've since learned to use the removing one stud method. especially when putting the engine in. it saves some time to line it up prior to dropping it in.

when removing the engine there's a couple different ways to do it. i removed it from the top because i am still somewhat stuck on the old school method. after pulling a few of these, i've found that it is possible to pull it from the bottom as well.

Pulling from the top:

you will need to remove the CV joints,

pull out the wiring and tuck it onto the motor or remove it completely,

use caution to tilt the engine out of the engine bay

possibly remove the hood.

You can see the engine was tilted to the trans side to clear the trans mount. you can remove the trans mount to gain some clearence when pulling the engine. most times you will have trouble with the back mount. this one for some reason will not come out straight sometimes. you can use a small hammer to tap out the stud that goes through the stud closest to the passenger side(us passanger) and it will allow the mount to slip out easier if you come from the top. when you put the engine back in, you can simply put the stud back in and use an impact gun to run it back in.

Pulling the engine from the bottom.

you will need to again remove the wiring, or tuck it onto the engine.

one of the benefit of removing from the bottom, you can leave the CV joints in(just make sure they are not captive like passing through the frame) doing this allows you to not have to spill trans fluid ALL OVER everything. then again you should use the drain plug and drain the fluids first. but if you take a good look at the pics you can see i didn't and there's fluid residue all over the garage floor.

when you plan to remove from the bottom, you will need to remove the whole subframe. there should be 8-12 bolts depending on what your suspension is like. the clip i had used a different lower arm than my car did. so luckily i had an extra subframe from another parts car and i used that instead. if you choose to do it this way, the Home depot dolly comes in handy. you can place one under the engine/subframe and then use the engine hoist to lower the engine onto the dolly. once everything is free, then you can use the engine hoist to raise the body of the car over the engine and roll the engine out. i've successfully done it this way several times.

when you have the parts out, this is the perfect time to change sway bar if you choose to. fishing it through the suspension and over the exhaust is kind of a bear.

below are the pictures associated with this. you can see i used some cardboard to protect the condenser while i pulled the engine. i also pulled the AC compressor on the side and used a piece of wire to tie it up out of the way. i could have made a mount to adapt it to the 20V mount like my friend did, but instead i used the 20V compressor. make sure you remove all rubber lines, hard lines, wires, etc and support the engine with an engine hoist prior to removing any engine mount bolts.

you can see the differences in the sub frame here. also the AE92 subframes are different as well so if you choose to somewhat follow this for an AE92 swap please make note of your sub frame

swapping the swaybar

Engine out. you can see the back mount was removed from the engine mount bolt. i've since learned to use the removing one stud method. especially when putting the engine in. it saves some time to line it up prior to dropping it in.

*Hint #3*

when you have the engine out, take the time to change ANYTHING else you need to. if you have high miles, i would seriously consider changing the steering rack i have to change mine now due to a leak and i am not looking forward to it. (see page 5 to see what i mean) also take the time to stock your engine bay. this will help incase you have a leak at some time in the future with your new engine. i like to use mineral spirits/paint thinner. it helps cut through layers of grease/ oil and i use them with rags or a small scrub brush. you can use a squirt bottle to spray it on, but again. check with your local laws regarding use and disposal of products as such. you can use engine degreaser, simple green etc. but make sure you use caution.

if you wanted to go to the next extreme, you could even paint your engine bay at this time. removing the rest of the items isn't that much more work. you are practically there if you choose to. just please don't do the "spray everything black" approach. it looks tacky if you murder out your engine bay.

before

after

when you have the engine out, you can start prepping the engine bay for the new motor. i chose to remove the harness from the motor in this pull on both the engine and the clip. you could also pull the harness from the body of the car along with the engine, but use caution when you do so. the chain could pinch/cut the wires, smash sensors etc. i chose to get the engine out, then figure out what i wanted to do with the wires. taking apart the dash you will need to remove both drivers side and glove box, as well as the center consul. because i did a auto to 5 speed swap, i had to change shifter, shift cable, and add in the pedal, clutch master, slave, hardline etc.

*Hint #4*

if you are doing an auto to manual swap, source your parts prior to attempting the swap. you can get 5 speed parts from Geo prizm of the 1993-1998ish range if you can't find them from corolla. it should bolt in.

when you take the parts, take the brake pedal as well. it's narrower and will allow you more room when using the clutch. you can cut the auto pedal if needed, but i got the parts from the junkyard for $40, clutch pedal, brake pedal, master, slave hard line.

when drilling the holes for the clutch master, it's best to bolt in the pedal to the top bolt first, then mark your holes. there is a small filler piece in the floor pad under the dash. it can be used to locate the pedal assembly. then use a sharpie to mark the holes. i used a step bit to drill the mounting holes, but used a hole saw to actually cut the pushrod hole. under my initial mock up, i used a celica clutch slave because i couldn't find the pedal assembly and didn't want to be dead in the water. the pedal unfortuantely didn't work. under the dash is a little different but i lucked out when i finally got the pedal. you will need to loosen and pull forward the brake booster for the hard line to pass behind it. also this is the best time to add in the manual trans brake pedal. the hole size i used is 1 1/2" or 38MM.

***** i'll get the size of the hole saw i used for the clutch master hole when i get a chance.******

edit it's 1 1/2" or 38MM.

when you have the engine out, take the time to change ANYTHING else you need to. if you have high miles, i would seriously consider changing the steering rack i have to change mine now due to a leak and i am not looking forward to it. (see page 5 to see what i mean) also take the time to stock your engine bay. this will help incase you have a leak at some time in the future with your new engine. i like to use mineral spirits/paint thinner. it helps cut through layers of grease/ oil and i use them with rags or a small scrub brush. you can use a squirt bottle to spray it on, but again. check with your local laws regarding use and disposal of products as such. you can use engine degreaser, simple green etc. but make sure you use caution.

if you wanted to go to the next extreme, you could even paint your engine bay at this time. removing the rest of the items isn't that much more work. you are practically there if you choose to. just please don't do the "spray everything black" approach. it looks tacky if you murder out your engine bay.

before

after

when you have the engine out, you can start prepping the engine bay for the new motor. i chose to remove the harness from the motor in this pull on both the engine and the clip. you could also pull the harness from the body of the car along with the engine, but use caution when you do so. the chain could pinch/cut the wires, smash sensors etc. i chose to get the engine out, then figure out what i wanted to do with the wires. taking apart the dash you will need to remove both drivers side and glove box, as well as the center consul. because i did a auto to 5 speed swap, i had to change shifter, shift cable, and add in the pedal, clutch master, slave, hardline etc.

*Hint #4*

if you are doing an auto to manual swap, source your parts prior to attempting the swap. you can get 5 speed parts from Geo prizm of the 1993-1998ish range if you can't find them from corolla. it should bolt in.

when you take the parts, take the brake pedal as well. it's narrower and will allow you more room when using the clutch. you can cut the auto pedal if needed, but i got the parts from the junkyard for $40, clutch pedal, brake pedal, master, slave hard line.

when drilling the holes for the clutch master, it's best to bolt in the pedal to the top bolt first, then mark your holes. there is a small filler piece in the floor pad under the dash. it can be used to locate the pedal assembly. then use a sharpie to mark the holes. i used a step bit to drill the mounting holes, but used a hole saw to actually cut the pushrod hole. under my initial mock up, i used a celica clutch slave because i couldn't find the pedal assembly and didn't want to be dead in the water. the pedal unfortuantely didn't work. under the dash is a little different but i lucked out when i finally got the pedal. you will need to loosen and pull forward the brake booster for the hard line to pass behind it. also this is the best time to add in the manual trans brake pedal. the hole size i used is 1 1/2" or 38MM.

***** i'll get the size of the hole saw i used for the clutch master hole when i get a chance.******

edit it's 1 1/2" or 38MM.

Ok sorry for the delay, life's been kicking me lately. lots of issues. so where did i leave off.

*HINT # 6* WIRING

there are SEVERAL methods to the madness of wiring. personally i sent my harness off to DR Tweak from phoenix tuning and spent roughly $590 with shipping ($40 to ship it there). i did pay for the rush service and shipped it to him on a Thursday. i shipped both the Blacktop harness as well as the AE102 stock engine harness. i received it back the following Tuesday. So well worth the price of expedite.

There are people that can do your wiring as welll. MR220V on club 4ag can build a harness from your existing AE102 harness for roughly $330. after reading up on this i did find that the AE102 harness uses the same exact plug as a ST and BT. you can find the pin outs on CLUB4ag as well as other sites and if you are gutsy enough you too can build your own harness.

Blacktop Pinout

Silvertop Pinout

i plan to do it for my next swap. i also found out that the distributor plug is the same as some 90's celica/camry with 5sfe engine. the coil and ignitor(as well as plugs) can be sourced from a 90's 4runner/sr5 pickup with 3VFE V6 i believe. i'm still on the search for what ever else i will need. but i believe for your trans you use your existing.

here's a pic of the distributor plug

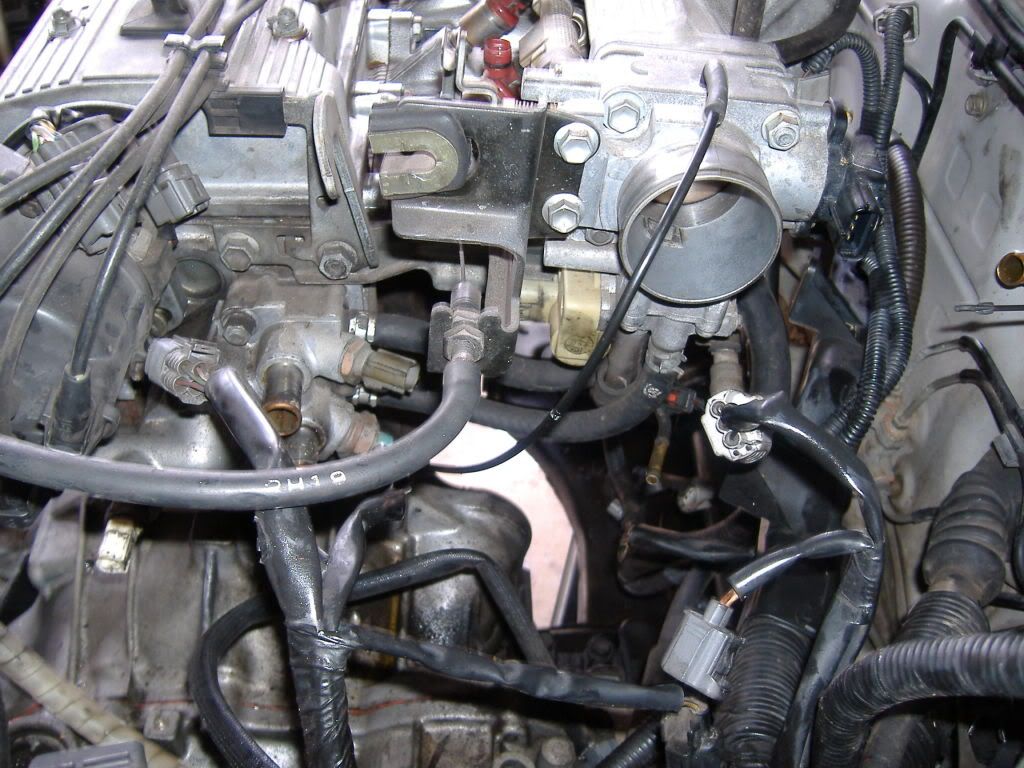

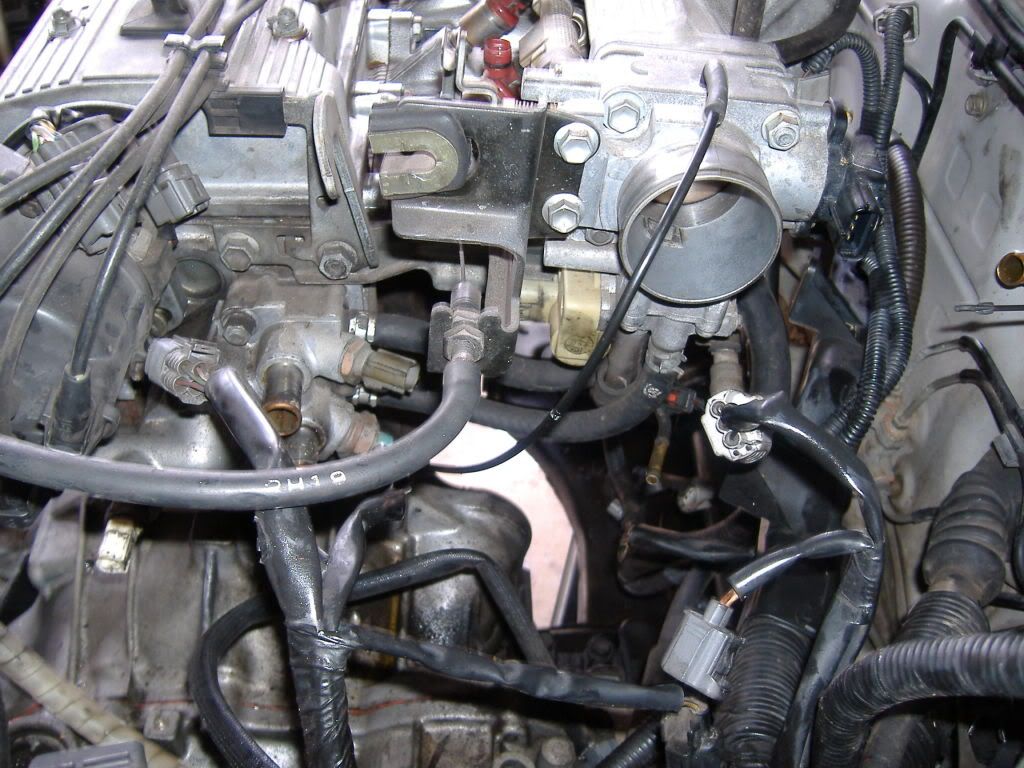

Also when you are in the Celica, you can take the long Throttle cable. if your AE101/102 has cruise control, you can use that instead. a friend of mine did this routing his cable under the ITB's. as you can see my cable comes all the way around by the radiator.

*HINT # 6* WIRING

there are SEVERAL methods to the madness of wiring. personally i sent my harness off to DR Tweak from phoenix tuning and spent roughly $590 with shipping ($40 to ship it there). i did pay for the rush service and shipped it to him on a Thursday. i shipped both the Blacktop harness as well as the AE102 stock engine harness. i received it back the following Tuesday. So well worth the price of expedite.

There are people that can do your wiring as welll. MR220V on club 4ag can build a harness from your existing AE102 harness for roughly $330. after reading up on this i did find that the AE102 harness uses the same exact plug as a ST and BT. you can find the pin outs on CLUB4ag as well as other sites and if you are gutsy enough you too can build your own harness.

Blacktop Pinout

Silvertop Pinout

i plan to do it for my next swap. i also found out that the distributor plug is the same as some 90's celica/camry with 5sfe engine. the coil and ignitor(as well as plugs) can be sourced from a 90's 4runner/sr5 pickup with 3VFE V6 i believe. i'm still on the search for what ever else i will need. but i believe for your trans you use your existing.

here's a pic of the distributor plug

Also when you are in the Celica, you can take the long Throttle cable. if your AE101/102 has cruise control, you can use that instead. a friend of mine did this routing his cable under the ITB's. as you can see my cable comes all the way around by the radiator.

Onto hoses.... AC and Power steering.

on my car i used the JDM equipment as much as possible. the whole reason for getting the clip was to make it as seamless as possible. i was able to integrate most of the lines into my Swap but if i had to do it again there are some shortcuts i've learned thanks to my friend. he did a 20V blacktop swap roughly the same time as me, but i got mine running about a month before he did. he only started with an engine, ecu, harness. he wound up using the USDM AC pump, and making an adapter plate to allow it to work with the JDM AC pump mount. doing this he eliminated the need to evacuate the AC system and make custom AC lines as i did.

on my AC lines one is the USDM one and one is a hybrid using the USDM fitting on the fender side, and JDM fitting on the pump side.

*HINT #7*

if you do get custom lines made make sure you discuss with the person making them. my local Hydraulic/air line shop actually cut and recrimped my AC lines. they clocked one fitting in the wrong place so i had to take it back and have them cut and weld it. then when i had it filled, it was still leaking so again they had to reweld it. had i done what my friend did, i would have eliminated this.

Power steering. now this is where had i done more research i could have saved some money. i wound up using the hard lines from the japan clip and replacing all the rubber. my line cost me $150 because of all the fittings that had to be welded in in order to put in the idle up vacuum fitting. this is only required for an automatic car, so if you are standard you can eliminate it and just plug the fittings. don't be tempted to just loop the fittings on the engine side together because you will have a constant vacuum leak and it will cause your idle to be higher than the 800rpm normal.

here's a pic of the fittings that can be eliminated.

and a pic of the whole line.

on a side note, slickgeoprizm asked me in pm if i think a tercel power steering hose would work. my friend actually used a tercel tank on his swap, so there is a possibility that you may be able to use the USDM tercel setup, tank, lines etc and make it work. you may need to lengthen the rubber lines, but this is minor. i'll see if i can find some pics of tercel setup or if i find it in the junkyard i will snap a pic to compare.

on my car i used the JDM equipment as much as possible. the whole reason for getting the clip was to make it as seamless as possible. i was able to integrate most of the lines into my Swap but if i had to do it again there are some shortcuts i've learned thanks to my friend. he did a 20V blacktop swap roughly the same time as me, but i got mine running about a month before he did. he only started with an engine, ecu, harness. he wound up using the USDM AC pump, and making an adapter plate to allow it to work with the JDM AC pump mount. doing this he eliminated the need to evacuate the AC system and make custom AC lines as i did.

on my AC lines one is the USDM one and one is a hybrid using the USDM fitting on the fender side, and JDM fitting on the pump side.

*HINT #7*

if you do get custom lines made make sure you discuss with the person making them. my local Hydraulic/air line shop actually cut and recrimped my AC lines. they clocked one fitting in the wrong place so i had to take it back and have them cut and weld it. then when i had it filled, it was still leaking so again they had to reweld it. had i done what my friend did, i would have eliminated this.

Power steering. now this is where had i done more research i could have saved some money. i wound up using the hard lines from the japan clip and replacing all the rubber. my line cost me $150 because of all the fittings that had to be welded in in order to put in the idle up vacuum fitting. this is only required for an automatic car, so if you are standard you can eliminate it and just plug the fittings. don't be tempted to just loop the fittings on the engine side together because you will have a constant vacuum leak and it will cause your idle to be higher than the 800rpm normal.

here's a pic of the fittings that can be eliminated.

and a pic of the whole line.

on a side note, slickgeoprizm asked me in pm if i think a tercel power steering hose would work. my friend actually used a tercel tank on his swap, so there is a possibility that you may be able to use the USDM tercel setup, tank, lines etc and make it work. you may need to lengthen the rubber lines, but this is minor. i'll see if i can find some pics of tercel setup or if i find it in the junkyard i will snap a pic to compare.

*Hint #8* poly front mount.

i would strongly suggest making the front mount on your 20V a polyurethane mount. there are several ways to do this, you could fill the mount like this link

forums.vwvortex.com/showthread.php?1188960

www.torontopaseoclub.com/modules.php?name=Forums&file=viewtopic&t=2123&sid=6824826b0661e6642b65c2d4dad67457

or do what i did and burn out all the rubber and actually make the whole mount polyurethane. you can use duct tape to seal the end, as well as locate the pin. i used polyurethane caulking from home depot, or was it lowes... either way it will come in either black or grey in a caulking tube. its roughly $10 and after using it for 1 year i can say it's hasn't torn. i recommend doing it in advance to locating your engine. it takes a few days for the polyurethane to fully cure. using the duct tape will allow you to remove everything and make it smooth. i used a piece of plexiglass to locate the pin in relationship to the mount prior to burning out the rubber. then once i was ready i went ahead and just filled the mount with the pin in the middle with the polyurethane . it works really well, but i'm not sure if i'd reccomend doing all 4 mounts. the front mount takes the most abuse so i'd DEFINATLEY do that one. unfortunately i don't have a pic of this, but the links has some good pics.

i actually used paint thinner on my finger to smooth out my mount so it wouldn't have the lumps like those did.

***i'll get a pic of the polyurethane i used from HD when i get a chance.***

i would strongly suggest making the front mount on your 20V a polyurethane mount. there are several ways to do this, you could fill the mount like this link

forums.vwvortex.com/showthread.php?1188960

www.torontopaseoclub.com/modules.php?name=Forums&file=viewtopic&t=2123&sid=6824826b0661e6642b65c2d4dad67457

or do what i did and burn out all the rubber and actually make the whole mount polyurethane. you can use duct tape to seal the end, as well as locate the pin. i used polyurethane caulking from home depot, or was it lowes... either way it will come in either black or grey in a caulking tube. its roughly $10 and after using it for 1 year i can say it's hasn't torn. i recommend doing it in advance to locating your engine. it takes a few days for the polyurethane to fully cure. using the duct tape will allow you to remove everything and make it smooth. i used a piece of plexiglass to locate the pin in relationship to the mount prior to burning out the rubber. then once i was ready i went ahead and just filled the mount with the pin in the middle with the polyurethane . it works really well, but i'm not sure if i'd reccomend doing all 4 mounts. the front mount takes the most abuse so i'd DEFINATLEY do that one. unfortunately i don't have a pic of this, but the links has some good pics.

i actually used paint thinner on my finger to smooth out my mount so it wouldn't have the lumps like those did.

***i'll get a pic of the polyurethane i used from HD when i get a chance.***

ok onto the swap.

**HINT #9**

when you install the engine it's easiest to place the harness on the motor than to try to reach around and install all the plugs. Also i would strongly recommend changing things like water pump, timing belt at the minimum. to get a water pump, you may need to get it from a japan dealer or something. i was lucky enough to find the timing belt from here:

www.tweakit.net/shop/product_info.php?currency=USD&cPath=568_569_587&products_id=6808

the BT is a 111 tooth belt, the ST is a 110 tooth belt. make sure you get the correct one for the correct application. there is a tensioner on there that looks like a little shock absorber. when you pull out the belt it will spring out. you will need to use a vise or something of the sort to push the piston back in, then use a small wire/pin to lock the shaft in to reinstall it. i used the back of a rivet to hold it till i got the belt back on and then installed it before pulling the pin out.

the site also has some hop up parts, studs, head gaskets etc. pricing on the timing belt wasn't too bad. i think it came up at $60 shipped.

water pump etc i got from japan. i can't remember how much i paid for them and i didn't use them yet. gonna save it incase i gotta rebuild.

here's a pic of everything on the engine ready to drop in.

also here's a pic of how you can lift the front of the car up high enough to slide the engine under if you have it on the cradle with the suspension arms still attached. much easier on the back.

When you do drop it in weather it be from the top or bottom, try to make sure you have any hoses, lines, cables, wires etc that come from the body set aside so they don't interfere with lining up the engine.

you can see in this pic when we dropped the engine into my bro's wagon i actually had it all shrink wrapped, just left the chain on the engine and then shrinked it all up.

his engine came in from the bottom. if you do it this way, you will still need to rest the car on jack stands, but you will need to pick the car up using the hoist. we used the bolt on the bottom of the front cross member where the front trans mount bolts in to raise the car body up high enough to clear the engine on the moving dolly. once it's somewhat in the right place, then you will need to lower the body down and then use the hoist to pick up the engine to line things up. if you come in from the top, you will need to angle the engine in lowering the trans side down first. rest it ontop the cross member reposition the chain and then try to pick the engine up level to line up the mounts.

here's a pic of taking the engine out of the clip. and somewhat the angle needed to get it to clear everything.

the back mount is the hardest to get in. you may need to tap out the studs, or atleast one of the studs to allow it to position in. once everything is lined up then you tighten things up. leave everything loose until the engine is located on all mounts. i believe you need a 19mm, and a 14mm if you are doing the whole clip method. if you are just doing engine mounts and dropping it in from the top and left the full suspension in, you will need a 17mm.

one more tip. i would reccomend taking off the mount on the trans until you get the motor level in the engine bay. then bolt it back together. it allows a little more room if you coming in from the top.(you can see in the pic above it's off the trans). from the bottom it should line up. the timing cover side i took that mount apart too. it's one bolt and 2 nuts on the engine side, and a few 10mm on the inner fender. just make sure you are careful around the AC lines if you want to make sure your AC will still work.

here's pics of my engine located on all mounts, minus the header. i lowered it in from the top so i chose to add in more room to wiggle when lining up the mounts. if you do the clip method, you will need to make sure the exhaust is on first, or you will have to separate it and it's a little more work to fish it through between the engine and subframe.

once the engine is in, you can start routing all the hoses and wires back to their correct locations. everything should bolt back in.

**HINT #9**

when you install the engine it's easiest to place the harness on the motor than to try to reach around and install all the plugs. Also i would strongly recommend changing things like water pump, timing belt at the minimum. to get a water pump, you may need to get it from a japan dealer or something. i was lucky enough to find the timing belt from here:

www.tweakit.net/shop/product_info.php?currency=USD&cPath=568_569_587&products_id=6808

the BT is a 111 tooth belt, the ST is a 110 tooth belt. make sure you get the correct one for the correct application. there is a tensioner on there that looks like a little shock absorber. when you pull out the belt it will spring out. you will need to use a vise or something of the sort to push the piston back in, then use a small wire/pin to lock the shaft in to reinstall it. i used the back of a rivet to hold it till i got the belt back on and then installed it before pulling the pin out.

the site also has some hop up parts, studs, head gaskets etc. pricing on the timing belt wasn't too bad. i think it came up at $60 shipped.

water pump etc i got from japan. i can't remember how much i paid for them and i didn't use them yet. gonna save it incase i gotta rebuild.

here's a pic of everything on the engine ready to drop in.

also here's a pic of how you can lift the front of the car up high enough to slide the engine under if you have it on the cradle with the suspension arms still attached. much easier on the back.

When you do drop it in weather it be from the top or bottom, try to make sure you have any hoses, lines, cables, wires etc that come from the body set aside so they don't interfere with lining up the engine.

you can see in this pic when we dropped the engine into my bro's wagon i actually had it all shrink wrapped, just left the chain on the engine and then shrinked it all up.

his engine came in from the bottom. if you do it this way, you will still need to rest the car on jack stands, but you will need to pick the car up using the hoist. we used the bolt on the bottom of the front cross member where the front trans mount bolts in to raise the car body up high enough to clear the engine on the moving dolly. once it's somewhat in the right place, then you will need to lower the body down and then use the hoist to pick up the engine to line things up. if you come in from the top, you will need to angle the engine in lowering the trans side down first. rest it ontop the cross member reposition the chain and then try to pick the engine up level to line up the mounts.

here's a pic of taking the engine out of the clip. and somewhat the angle needed to get it to clear everything.

the back mount is the hardest to get in. you may need to tap out the studs, or atleast one of the studs to allow it to position in. once everything is lined up then you tighten things up. leave everything loose until the engine is located on all mounts. i believe you need a 19mm, and a 14mm if you are doing the whole clip method. if you are just doing engine mounts and dropping it in from the top and left the full suspension in, you will need a 17mm.

one more tip. i would reccomend taking off the mount on the trans until you get the motor level in the engine bay. then bolt it back together. it allows a little more room if you coming in from the top.(you can see in the pic above it's off the trans). from the bottom it should line up. the timing cover side i took that mount apart too. it's one bolt and 2 nuts on the engine side, and a few 10mm on the inner fender. just make sure you are careful around the AC lines if you want to make sure your AC will still work.

here's pics of my engine located on all mounts, minus the header. i lowered it in from the top so i chose to add in more room to wiggle when lining up the mounts. if you do the clip method, you will need to make sure the exhaust is on first, or you will have to separate it and it's a little more work to fish it through between the engine and subframe.

once the engine is in, you can start routing all the hoses and wires back to their correct locations. everything should bolt back in.

**Hint #10**

when i was looking back i forgot to mention i would reccomend changing belts and hoses if needed. i changed the belts but found out one of the belts is an odd size. i can't remember the belt numbers i wound up getting. i'll see if i can get them friday when i'm at my shop. when installing them leave the tensioners loose. there's swing adjustments on both the alternator and the power steering. you can see the alternator adjustment in this pic. it's a PITA to adjust these sometimes. mine was slipping for a while.

as for the hoses. there's 2 hoses on the 20V that go to the JDM side brake booster. on the US model there's a hardline that goes to the intake for the vacuum for the booster. i wound up using a plastic T fitting and tapping both the vacuum ports to one to go to the us booster. i will get a pic of this later on too.

so continuing on. you can start to put back all the accessories power steering pump, water tank wires hoses, radiator etc.

**HINT #11**

make sure your coil and ignitor are grounded. if not the car won't run. there's also a small capacitor that's attached to the same area. it will need to either be left hanging or mounted a different way. the brake booster interferes with the mounting plate.

the MAP sensor can mount back to the US mount on the firewall unless you go with a TRD tower bar of some sort. i had mine floating around for a while because i was too lazy to get a longer hose for it.

you can continue installing the exhaust. in my case i lucked out and got a header.

**Hint #12**

the USDM axles should work. they may touch the stock exhaust manifold though. the JDM one has an intermediate shaft that routes straight to the passenger side. then it has equal length shafts to the hubs. this is to decrease the chance of torque steer under heavy acceleration. i've also heard that some aftermarket headers (HKS) also touch if you use the USDM shaft. i guess i lucked out, but the US shafts aren't as beefy as the JDM ones. maybe i should look into getting GT4 shafts or something but for now, and what i do, the USDM AE101 shafts are sufficient.

once you get the shafts in, the remaining is just to button everything back up. i used the USDM radiator on my car and have never had over heating issues. most times the car barely gets over the 1/4 temp line. and i run the AC constantly. sometimes sitting in traffic it will creep up to just under 1/2 but never pegged the needle.

when i was looking back i forgot to mention i would reccomend changing belts and hoses if needed. i changed the belts but found out one of the belts is an odd size. i can't remember the belt numbers i wound up getting. i'll see if i can get them friday when i'm at my shop. when installing them leave the tensioners loose. there's swing adjustments on both the alternator and the power steering. you can see the alternator adjustment in this pic. it's a PITA to adjust these sometimes. mine was slipping for a while.

as for the hoses. there's 2 hoses on the 20V that go to the JDM side brake booster. on the US model there's a hardline that goes to the intake for the vacuum for the booster. i wound up using a plastic T fitting and tapping both the vacuum ports to one to go to the us booster. i will get a pic of this later on too.

so continuing on. you can start to put back all the accessories power steering pump, water tank wires hoses, radiator etc.

**HINT #11**

make sure your coil and ignitor are grounded. if not the car won't run. there's also a small capacitor that's attached to the same area. it will need to either be left hanging or mounted a different way. the brake booster interferes with the mounting plate.

the MAP sensor can mount back to the US mount on the firewall unless you go with a TRD tower bar of some sort. i had mine floating around for a while because i was too lazy to get a longer hose for it.

you can continue installing the exhaust. in my case i lucked out and got a header.

**Hint #12**

the USDM axles should work. they may touch the stock exhaust manifold though. the JDM one has an intermediate shaft that routes straight to the passenger side. then it has equal length shafts to the hubs. this is to decrease the chance of torque steer under heavy acceleration. i've also heard that some aftermarket headers (HKS) also touch if you use the USDM shaft. i guess i lucked out, but the US shafts aren't as beefy as the JDM ones. maybe i should look into getting GT4 shafts or something but for now, and what i do, the USDM AE101 shafts are sufficient.

once you get the shafts in, the remaining is just to button everything back up. i used the USDM radiator on my car and have never had over heating issues. most times the car barely gets over the 1/4 temp line. and i run the AC constantly. sometimes sitting in traffic it will creep up to just under 1/2 but never pegged the needle.

so i know i'm probably missing things.. and my initial write up was here:

www.67-72chevytrucks.com/vboard/showthread.php?t=334312

but at this point i will open this back up for comments and questions. here's some final pics of my car with the old tower bar in minus the plug wire cover and the trd tower bar in and the plug cover in as a final product. the most said comment is it's soo stock. looks factory. exactly how i wanted it to look.

also everyone says my car is the ultimate sleeper. nothing special until you see under the hood.

here's some more pics of my car hanging out with some friends cars at a cruise in, and at a lookout. i'm the big dude in the tan shirt at the lookout.

www.67-72chevytrucks.com/vboard/showthread.php?t=334312

but at this point i will open this back up for comments and questions. here's some final pics of my car with the old tower bar in minus the plug wire cover and the trd tower bar in and the plug cover in as a final product. the most said comment is it's soo stock. looks factory. exactly how i wanted it to look.

also everyone says my car is the ultimate sleeper. nothing special until you see under the hood.

here's some more pics of my car hanging out with some friends cars at a cruise in, and at a lookout. i'm the big dude in the tan shirt at the lookout.

forgot to add this in.... something i'm working on to make it pretty

Aww man, at least you tried. What are you planning to try next?

Aww man, at least you tried. What are you planning to try next?